Posted 25.4.19

Few things are more fascinating to watch than a cow having a good scratch while ‘playing’ with a brush. They enjoy grooming – it’s a natural behaviour that’s key to good health and welfare.

And work has revealed that it’s about so much more than just ‘scratching that itch’. Grooming, or ‘scouring and scraping’, is essential for removing fleas and other parasites, as well as promoting blood flow.

“It’s a natural instinct. If cows are in a field they’ll rub up against hedges, gates, posts, trees – anything that offers some resistance,” says Dairy Spares’ Tim Evanson.

“If they’re inside then troughs, railings, walls – anything solid – will also take the brunt of their grooming behaviour. And, if cow brushes are fitted, these will obviously be put through their paces.”

Winter Coats

He says that brushes will be particularly popular with cows at this time of year, as they’re losing their winter coats. “They’re itchy and need to stimulate hair shedding and blood flow.”

A good brush will not only stimulate blood flow, but also allow the cow to groom parts of her body that other ‘scratching posts’ can’t reach.

“They certainly enrich the cow environment. It’s clear to see that cows get a lot of pleasure from the brushes. And the fact that there are also health benefits is the icing on the cake really – and another good reason to consider investing in brushes.”

Mr Evanson adds that for brushes to be effective, bristle strength has to be good: “Too soft and they just won’t do the job. Remember, you have more than 650kg pushing up again it – it needs to stand up to that pressure.”

And there’s no need to take his word for it. In a trial, cows were monitored three months prior to brush installation and for a further six months after brushes were fitted. “The time cows spent grooming themselves was more than six times greater than before the brushes were installed,

“And ask any producer who has fitted brushes and they will tell you that the cows never leave them alone – they’re almost in constant use.”

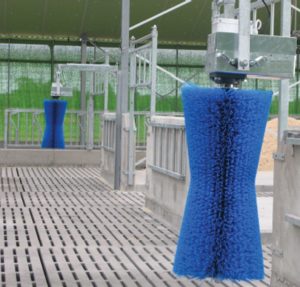

Mechanical Brushes

Work has also shown that cows are more active in systems where brushes are fitted. “Particularly mechanical brushes,” says Mr Evanson. “Once cows have gone to groom themselves they are then more likely to visit the feed fence or the water trough. The brushes have been shown to increase milk yields in some cows.”

Siting is important to get right. “The brushes, as you can imagine, remove a lot of dust and dirt and hair. So next to water troughs is not ideal for that reason alone. And it’s also important that they’re placed away from water troughs and feed fence access. Care must be taken to avoid disrupting cow flow.”

Mechanical brushes start rotating once cows press up against them, and some contra-rotate too. However, because they’re run with electric motors, they should be sited indoors. “Some producers do install them outside in yards, but they should ideally be in the cow shed.”

Non-mechanical ‘swing’ or ‘sprung’ brushes siting is not as stringent. “They should be installed where the cows will use them, when they’re housed or when they come inside during the summer for buffer feeding. Cows love to use them and so regular cleaning and maintenance to help reduce wear is important.”

Good Position

He recommends taking advice on exactly where to site them in the cow house. “The traverses between beds can be a good place, if they’re wide enough. But if you’re not sure, ask a consultant or the company you’re planning to buy the brushes from. They should have the knowledge and expertise to get this right on your unit.”

Cow flow can also suffer if there are too few brushes installed. “It can actually serve to create stress, rather improve cow welfare and comfort, if the brushes themselves are a ‘pinch point’. Cows queuing to use the brushes or dominant cows preventing others from using them may become an issue where are aren’t enough brushes to go around.”

For that reason, Mr Evanson says it’s not a good idea to just put in one brush to ‘see if the cows take to it’. “Believe me, they will. And they’ll fight over it and it will get ‘hammered’. It will appear to keep the cows happy and busy for so long, but then it will break.”

One mechanical brush should cater for between 50 and 60 cows: “That’s the limit – they will still work it hard and it will run for most of the day with that number of cows.”

A non-mechanical non-moving brush installed on a wall or rail cannot offer all-round access and so will service fewer cows.

A non-mechanical non-moving brush installed on a wall or rail cannot offer all-round access and so will service fewer cows.

“They’re robust pieces of kit and, if the brushes are routinely cleaned and the key moving parts greased regularly, they should provide a good service.

Study highlights cow brush health and production benefits

Studies on swinging cow brushes, that looked at milk production and mastitis incidence. The US-based work showed that second-lactation cows produced 3.5% (1kg) higher daily milk yield. And clinical mastitis was reduced by 34% in the cows in second and higher lactation in the cow-brush pens.

The work also revealed that cows in a pen with a mechanical brush increased their grooming time approximately five-fold compared to a pen without such a brush. The researchers concluded that a grooming device helps to satisfy the cow’s need for grooming while at the same time improving cow cleanliness. Both these factors (better ‘welfare’ and cleaner cows) may have an impact on disease occurrence and on milk production.

And the increased activity of the cow may lead to less metabolic diseases, better digesting and eventually in higher milk production.

Although the intuitive concept of the swinging cow brush being associated with better productivity and increased health may be straightforward, no hard data exist to quantify this potential relationship. Therefore a comparison study of cows experiencing a cow brush was designed, including a contemporary control and pre-study baseline measurements.

To view our full range of cattle brushes, please click here.